Artificial Intelligence in Nuclear Regulation

Artificial intelligence is beginning to move from research discussions into practical applications that could affect how nuclear power plants are licensed, monitored, and regulated. Three projects underway at the U.S. Department of Energy’s Argonne National Laboratory are exploring how AI tools could reshape nuclear safety analysis, regulatory review, and plant operations.

Evaluating AI Systems Under Current Regulations

One effort focuses on how AI systems themselves would be evaluated under existing nuclear safety regulations. In coordination with the U.S. Nuclear Regulatory Commission, Argonne researchers are testing an AI system at an experimental facility and subjecting it to a full regulatory review. The goal is to understand how AI-based tools for maintenance prediction, system modeling, and operational optimization align with current safety standards and oversight processes.

By evaluating AI under real regulatory conditions, the project aims to inform future guidance on how such technologies could be reviewed, validated, and approved.

Automating the Licensing Process

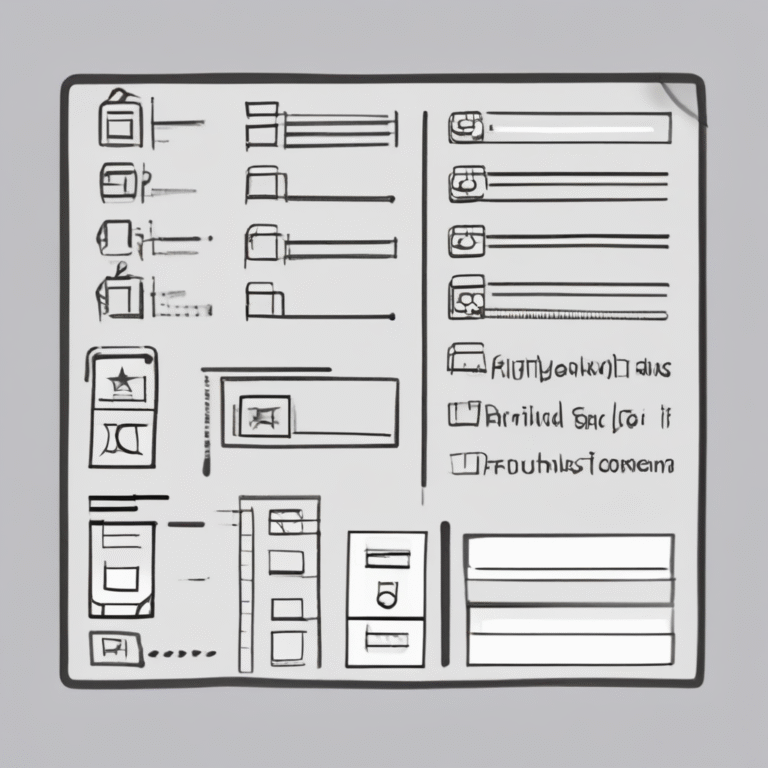

The second project targets the licensing process itself. Argonne is developing an AI-based framework intended to automate parts of the communication between reactor developers and regulators. Known as the Regulatory Context Protocol, the system uses AI agents to structure information exchange, track requirements, and ensure submissions align with regulatory expectations.

Licensing timelines remain a significant barrier for advanced reactor deployment, particularly for non-light-water designs. Automating routine interactions and improving information quality could reduce review delays and help both applicants and regulators manage increasingly complex submissions.

Monitoring and Fault Detection

The third initiative focuses on plant monitoring and fault detection. Argonne has developed a physics-based AI tool that combines digital twins of plant systems with real-time operational data. Unlike data-only approaches, the system incorporates physical principles to identify abnormal behavior such as sensor drift or cooling system issues.

The tool has been tested at Argonne’s Mechanisms Engineering Test Loop facility and has demonstrated the ability to detect problems early, before they result in equipment damage or forced outages.